How a Two-Stroke Glow Engine Works

The two-stroke glow or nitro engine is a simple and elegant concept. While there are many variations on the design, the basic elements remain unchanged.

There is a piston moving back and forth in a cylinder. The piston is connected by a hinged rod to a rotating crankshaft.

There is a combustion event on every other stroke of the piston (at the beginning of the down-stroke).

The combustion is caused by a platinum element in a heated glow plug, combined with a compressed fuel-air (and oil) mixture.

There are also intake, exhaust and a transfer ports, to move around fresh and used fuel. A carburetor is used to mix air with fuel in the required ratio for the power output needed.

See our How to Tune the Engine page for an in-depth look at how the carburetor works.

The beauty of this type of engine is its simplicity. The piston itself functions as a fuel-air-exhaust valve, eliminating the need for the extra parts found in the four stroke engine.

The engine is also its own fuel pump, as the movement of the piston pressurizes the crankcase.

The fuel carries its own oil, further simplifying the design. And last but not least, being able to remove the battery after the engine starts, due to the self-sustaining glow-plug, reduces weight considerably.

This is very desirable in a model airplane engine.

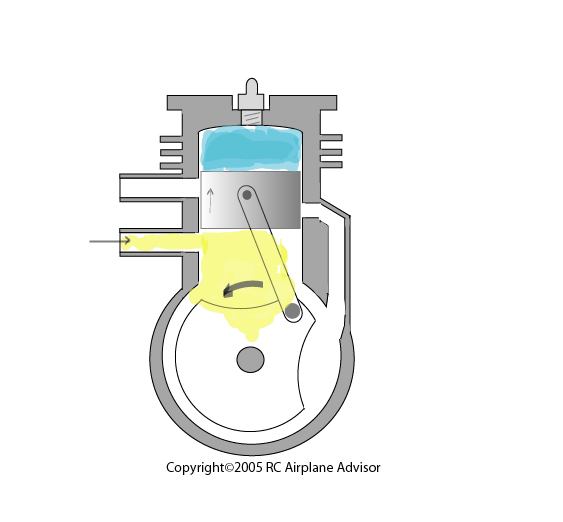

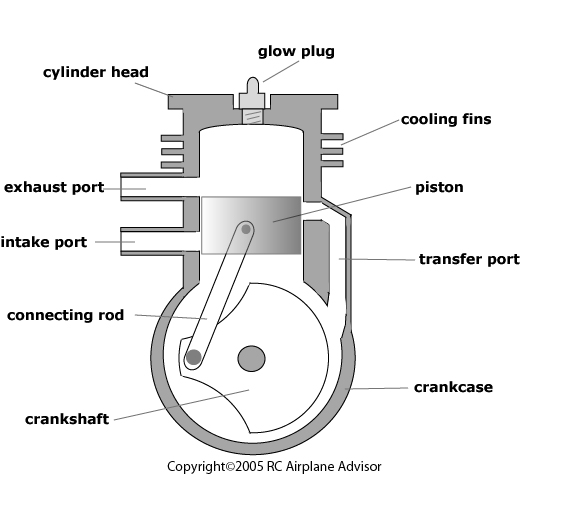

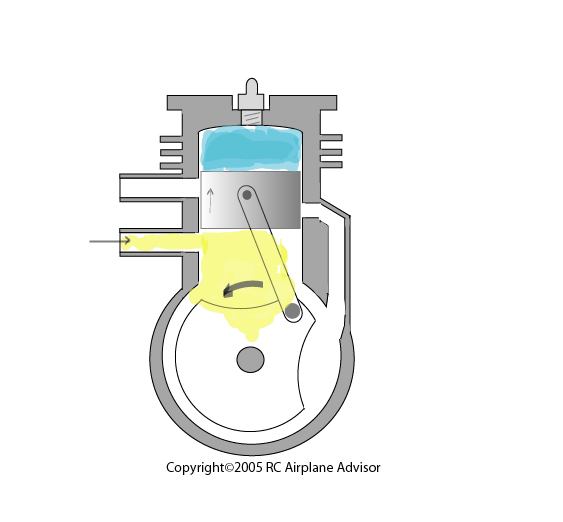

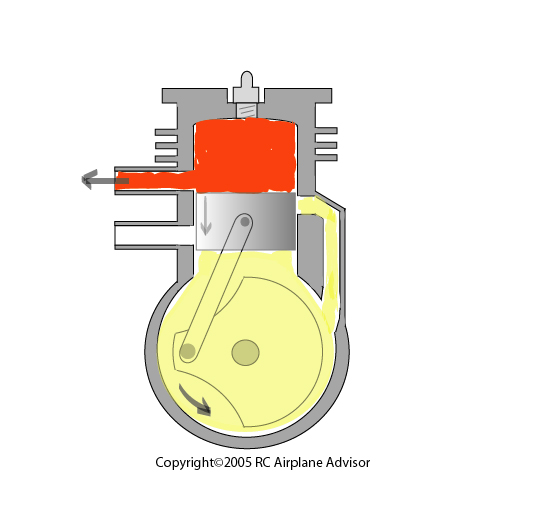

The basic two stroke glow engine design. For simplicity, the intake is shown here is at the side. A popular sport engine design is a front mounted carburetor, with intake through a hollow crankshaft. The intake of the fuel-air mixture begins when the piston uncovers the intake port while moving upwards. There is already a fuel-air mixture being compressed in the cylinder head above the piston.

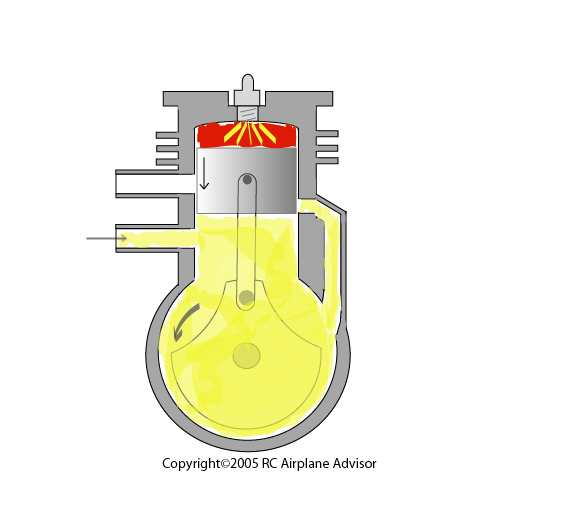

At the top of the compression stroke, the compressed fuel-air mixture is ignited by the hot glow plug. The resulting explosion of gases is what drives the piston downwards. Note that more fuel-air mixture has been drawn into the cylinder.

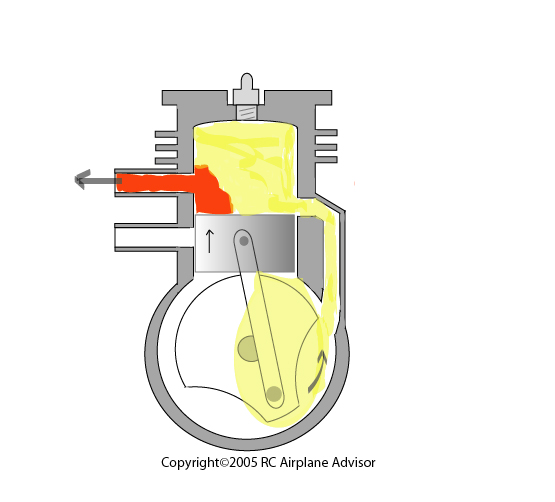

As the piston moves downwards, it uncovers the exhaust port. The exhaust gases flow out of that port. Note that the intake and transfer ports are both covered by the piston. Since the piston has a tight seal with the cylinder wall, this has the effect of pressurizing the fuel-air mixture that is below the piston in the crankcase.

As the piston moves down even further, the transfer port becomes uncovered. Remember that compressed fuel-air mixture in the crankcase? It now rushes into the cylinder head above the piston, helping to displace any remaining exhaust gases. The piston now starts back on its upward stroke.

We're back to the starting point. The fuel-air mixture that was just taken in starts to be compressed, as more mixture is taken in through the intake port. The cycle repeats itself.