How to Tune Your Engine

What is tuning and why would you want to do it? Tuning is simply adjusting your engine for best performance. The settings that it comes with from the factory may be a good starting point.

However, these engines are somewhat sensitive to the environment. You may need to adjust for higher altitude operation, or for temperature variations throughout the year. Changes in fuel type, or in wear as the engine breaks in, may also call for re-tuning.

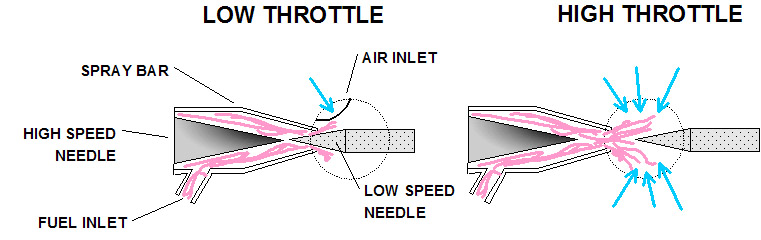

To understand how to tune your engine for best performance, it helps to first understand the function of the carburetor. This is a modified tube on the front of the engine.

It functions as the air inlet, pulls fuel from the tank, allows you to throttle the engine, as well as set the correct fuel-air mixture for best performance. There are many variations on carburetor (carb) designs; we will discuss the popular twin needle design.

This has a "high speed" as well as a "low speed" needle, which we'll discuss below.

The engine itself acts like a pump and creates its own air suction. (See also How the Two-Stroke Engine Works).

When the engine is running, the flow of air through the carb actually pulls fuel into the carb. This is accomplished by the Venturi effect.

When a fluid like air speeds up, its pressure decreases.

The inside of the carb opening gets narrower over its length, causing the air flow to speed up, and the pressure to decrease.

Another smaller tube called the spray bar is connected to the fuel inlet. The opening of the spray bar is positioned in the low pressure area, causing the fuel to be pulled into the engine's crankcase.

Copyright©2005 RC Airplane Advisor

Inside the typical carburetor body is a rotating barrel with a hole. The barrel has an arm that is connected to the throttle servo. Moving the throttle stick on the transmitter causes the barrel to (1) rotate, and (2) move inwards or outwards.

At low throttle stick, the barrel mostly blocks the hole that allows air into the engine. At high throttle, the barrel opens up fully, allowing maximum air in.

In addition, the rotating barrel at the same time moves a low speed needle to partially block or unblock the spray bar, controlling the amount of fuel released into the engine.

So now you understand what happens when you throttle up or down. Low throttle = less air and less fuel. High throttle = more air and more fuel.

To run properly, the engine needs the right ratio of fuel to air. This ratio is know as the mixture.

The carburetor needles (or screws) allow us to set the correct mixture, both at low and high throttle, for best operation of the engine.

Relatively more fuel to air is known as a "rich" mixture, whereas relatively less fuel to air is known as a "lean" mixture. A lean mixture generates more power, but also generates more heat.

Running the engine past its optimum lean point can result in damage to the metal parts, and should always be avoided. A rich mixture generates less power and less heat. Too rich and the engine might quit while you're flying, and just generally be harder to keep running.

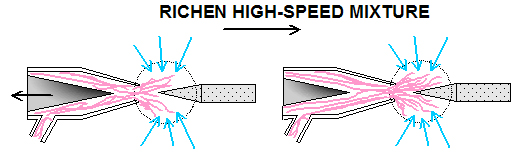

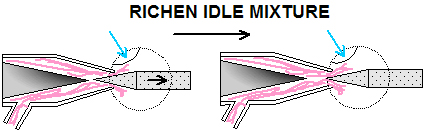

Both the low and high speed needles can be richened, or leaned out. Richening is usually turning them counter-clockwise, which pulls the needle away from the spray bar opening.

The high speed needle often has a thumb screw for manual operation, while the low speed is adjusted with a small screwdriver.

The high speed needle controls the total fuel flow into the engine, and affects the engine's behavior from half to full throttle. The low speed needle tends to have more of an effect from half throttle down to idle. So the high speed mixture is set with the engine at full throttle; the low speed is set after throttling back to idle. See detailed procedure below.

Copyright© RC Airplane Advisor

Tuning Procedure

1) Start with the factory recommended needle settings. If you have no idea what these settings should be, use the Needle Starting Point procedure in the next section (below).

2) Start the engine. If you don't know how, see our tutorial on How to Start the Engine.

3) With the engine or aircraft secured, open the throttle to full.

4) Lean the high speed needle slowly and watch and listen:

Too rich: lots of smoke, low pitched sound

Leaner: reduced smoke, sound starts changing to higher pitch

Leaner still: little smoke, max rpm reached

Too lean: very little smoke, max rpm can be heard falling off. Open the needle valve up 20 or 30 degrees from this point. If you have a tachometer, open the needle about 300 rpm less than max.

5) Still at high throttle, perform the pinch test. Briefly pinch then release the fuel tube going into the carb. If the engine momentarily speeds up, then slows back down, you're done. If the engine does not speed up, or quits, then it is too lean; richen the needle some more.

6) Now throttle back to idle; let the engine idle for a couple minutes.

7) Now perform another pinch test. This time pinch and hold the line. The engine will want to speed up and die (since you are effectively leaning it out). If it speeds up immediately, it's too lean, richen the low speed needle. It should take 4-6 seconds to speed up and begin to die. Any longer and it's too rich.

8) Also check the throttle transition. With the aircraft secured and engine idling for a couple minutes, advance the throttle quickly to fully open. If the engine hesitates, the low speed mixture is too rich.

Frequency: The low speed needle will seldom need adjusting. Do the pinch test for the high speed mixture before every flying session.

Needle Starting Point Procedure

Use this procedure if you don't know where to set your needle valves for initial operation.

1) Open the high speed needle 4-5 turns from the closed

position.

2) Fully close the low speed needle valve.

3) Place a clean piece of fuel tubing on the carb inlet.

(It needs to be clean because you're going to blow into it!)

4) Open the carb barrel from the closed position, about

20% of the full range.

5) Now blow into the fuel tubing while opening (richening) the low speed needle.

6) Stop turning the needle as soon as you feel or hear

the air blowing into the carb. This will be a small flow of air.

Remember that you want a small flow of fuel at low throttle, so this is a good

starting point.

7) Fully close the high speed needle.

8) Open the carb barrel to the full throttle position.

9) Now blow into the fuel tubing while opening (richening) the high speed needle.

10) Turn until the air flows freely into the carb.

This will be a large flow of air (compared to the low end needle setting).

Remember that you want a large flow of fuel at full throttle, so this is a good

starting point.

Back to the Model Airplane Engine page.