How a Four-Stroke Glow Engine Works

The four-stroke glow or nitro engine is an elegant concept, though not as simple as its two-stroke counterpart. While there are many variations on the design, the basic elements remain unchanged.

There is a piston moving back and forth in a cylinder. The piston is connected by a hinged rod to a rotating crankshaft.

There is a combustion event on every fourth stroke of the piston (at the beginning of every other down-stroke).

The combustion is caused by a platinum element in a heated glow plug, combined with a compressed fuel-air (and oil) mixture.

There are also intake and exhaust ports, to take in fresh fuel and remove used. A carburetor is used to mix air with fuel in the required ratio for the power output needed.

This engine has separate intake and exhaust valves. These are operated by a cam arrangement. The most common design is overhead valves that are opened by pushrods, and closed by return springs.

The fuel carries its own oil.

Being able to remove the battery after the engine starts, due to the self-sustaining glow-plug, reduces weight considerably. This is very desirable in a model airplane engine.

Advantages of Four-stroke versus Two-stroke:

4-strokes are quieter.

4-strokes generate much more torque and will swing larger props (at lower rpm).

4-strokes have a more realistic (deeper pitched) sound.

4-strokes get better fuel economy.

The first three of these advantages make four-strokes a good choice for scale models.

Disadvantages of Four-stroke versus Two-stroke:

4-strokes have more moving parts.

4-strokes can be trickier to adjust (e.g. valve adjustment).

4-strokes are usually more expensive.

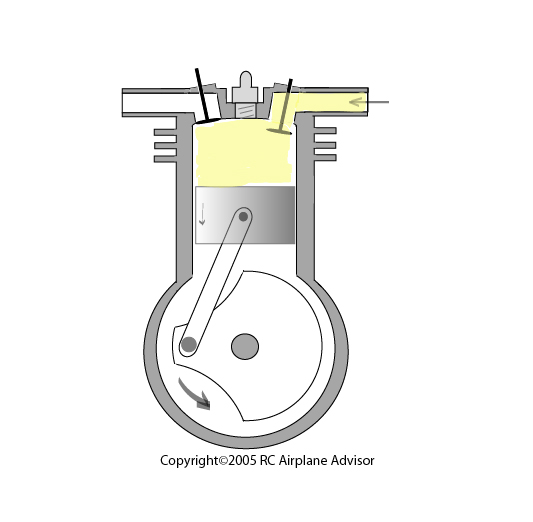

The parts of a typical four-stroke engine are shown below. For simplicity, the cams, pushrods and springs are omitted.

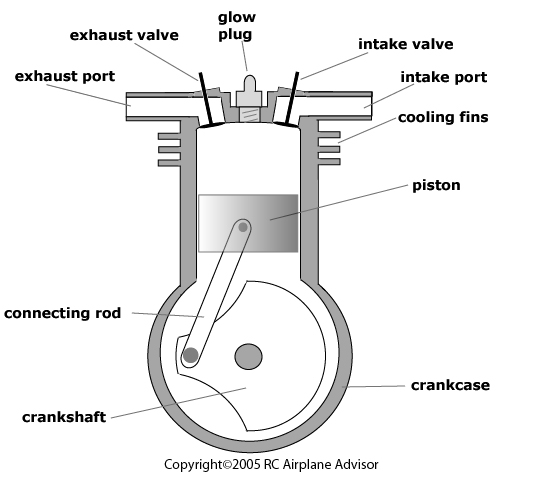

This is the intake stroke. The intake valve is opened and the piston moves downwards. The fuel-air mixture from the carb is taken into the cylinder head.

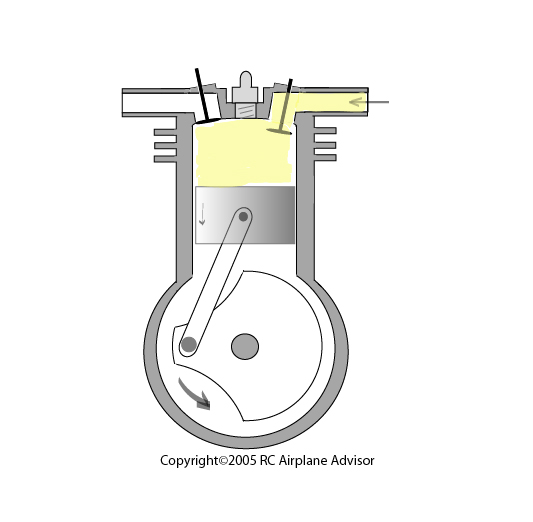

As the piston returns on the upward stroke, the intake valve closes. The fuel-air mixture is then compressed between the piston and the cylinder head.

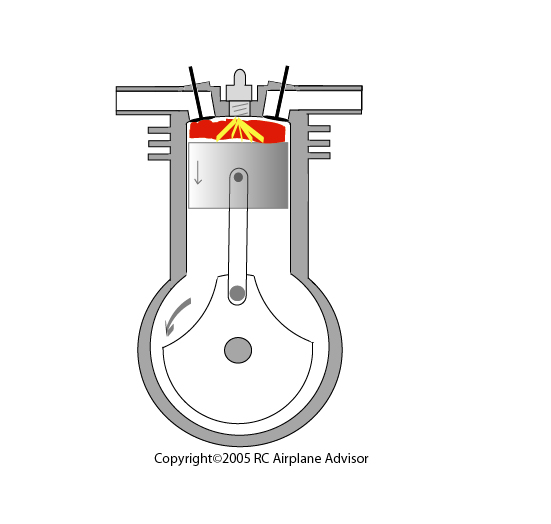

At the top of the compression stroke, the hot glow plug and the compressed mixture create combustion. The resulting explosion of gases drives the piston downwards on its power stroke.

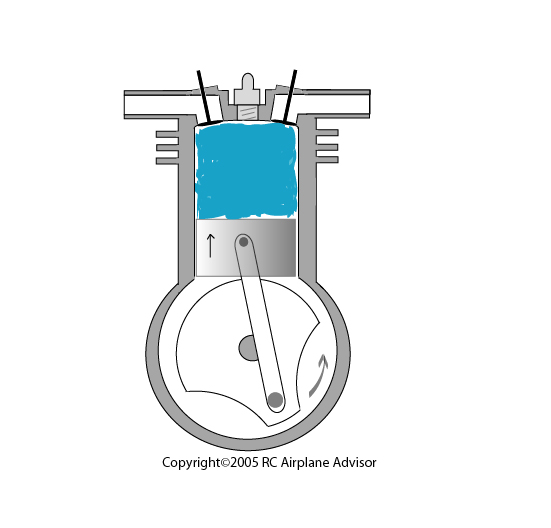

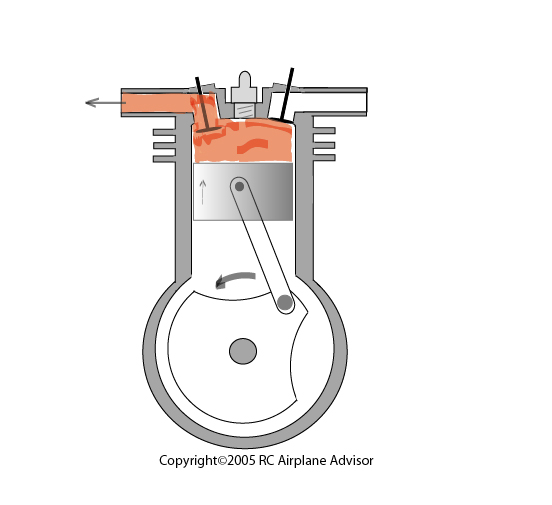

The momentum of the crankshaft carries the piston back on another upward stroke. The cam arrangement opens the exhaust valve, and the spent gases are pushed out of the exhaust port.

We're now back to the starting point with another intake stroke, and the cycle repeats itself.